Summary: Sieving to ascertain particle size distribution has a protracted historical past. First implementation of the method is comparatively cheap. Success, which show the fraction of particles that suit via a particular opening, are deemed simple to interpret. Even so, Considering that the analyzed particles instantly Get in touch with the sieve, sieve sizes transform with escalating use. Moreover, the activity of cleaning sieves improves labor prices.

Guide cleansing is rapid and handy thanks to the sieve’s hygienic style. Utilizing the bayonet mount and clamp ring blend, the sieve container might be eliminated easily. Therefore, cleaning the person elements is often a breeze. Cleaning nozzles may be added to your sieve housing being an choice for very simple WIP cleansing, in which compound residue from the sieve container is eradicated easily.

Commonly Asked Thoughts What's the usage of an ultrasonic separator? Ultrasonic separation allows for a lot easier separation of bulk powders which include steel powders, paints, chemicals or foodstuff powders.

Can ultrasonic deblinding sieves deal with different types and sizes of powders properly? Unquestionably. Ultrasonic deblinding sieves are made to manage a wide array of powders, which includes wonderful particles, tough-to-monitor elements, and those prone to agglomeration. These sieves is usually personalized with several mesh sizes and screen elements to accommodate certain powder attributes. Regardless of whether It really is pharmaceutical powders, chemical compounds, foods elements, or another sort of powder, ultrasonic deblinding sieves offer specific and reputable screening, making certain optimum separation effectiveness no matter powder size or composition.

How can ultrasonic deblinding sieves enhance powder sieving efficiency? Ultrasonic deblinding sieves are very helpful in enhancing powder sieving efficiency. By employing large-frequency vibrations, these sieves reduce blinding and blockages that generally manifest during the sieving method. The ultrasonic Electrical power dislodges particles, agglomerates, and various contaminants in the display area, making certain a reliable move of powder and decreasing downtime. This contributes to improved throughput, better screening accuracy, and greater efficiency, creating ultrasonic deblinding sieves an indispensable Instrument for reaching exceptional powder sieving performance. Statistic: Scientific studies have shown that ultrasonic deblinding sieves can improve sieving performance by as many as 300% when compared to regular strategies.

With that, This information will determine sample body weight, sieve size, reveal how each component Gains particle Assessment independently, and explain how they both of those operate together to generate trusted benefits.

Mesh sizes aren’t arbitrary – they’re ruled by different Global and field-certain expectations. These specifications ensure regularity and standardization of mesh sizes and mesh openings throughout various tests functions.

This cookie is ready because of the company Addthis. This cookie is used for social websites sharing monitoring assistance.

The time period sieve size is usually used to explain two aspects of a take a look at sieve: the diameter of your sieve body along with the mesh count in the sieve. For the objective of website this text; however, we are referring to the diameter of a exam sieve.

Though understanding sieve mesh sizes is very important, it’s equally important to understand the development and products used in sieves. In any case, the sturdiness and features of a sieve don’t just rely upon the mesh size, but in addition to the materials used in its construction.

Employing a sieve shaker might help retain the wire click here cloth’s functionality by making sure even distribution of particles for the duration of sieving.

A gaggle of sieves which has a mathematically defined list of opening sizes, wire diameters, and tolerances

They are also employed for that separation and classification of different factors in pharmaceuticals to meet the requirements of pharmaceutical procedures.

By routinely checking and validating sieve sizes, you can be certain precise and reliable particle size Investigation.

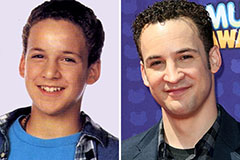

Ben Savage Then & Now!

Ben Savage Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!